The gas-water heat exchanger is used in the natural gas vacuum phase-change boiler, and its heat exchange efficiency is much higher than the water-water heat exchanger of the atmospheric pressure boiler by using the principle of phase change. As the whole unit operates under vacuum, the explosion hazard is completely avoided. Compared with traditional hot water boilers, this unit has unparalleled ease of operation. It is used to provide heating and sanitary hot water in various occasions such as hotels, offices, commercial and residential buildings.

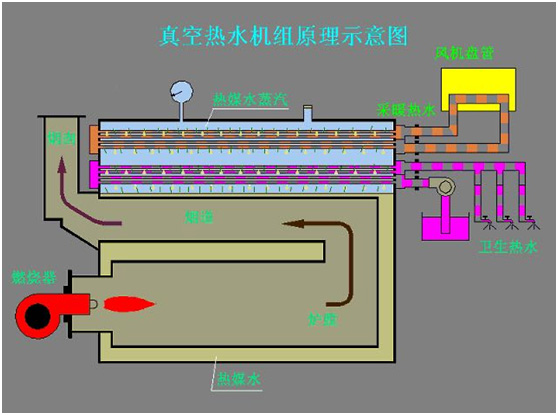

The whole structure of the natural gas vacuum phase change boiler is a negative pressure hot water unit. The unit is equipped with burner and a smoke pipe. The unit uses natural gas to burn in the furnace through a burner, and the heat generated by the combustion heats the heat medium water. The air inside has been vacuum out before commissioning, and the machine is in a vacuum status. The heat medium water is heated to about 30℃ and then evaporate in a vacuum state. The steam heat the hot water flowing in the heat transfer tube to provide it to the outside world hot water or sanitary hot water or for heating.

Natural gas vacuum phase change boiler

| model | VB-10 | VB-20 | VB-30 | VB-40 | VB-50 | VB-60 | VB-80 | VB-100 | ||

| Continuous output | 10 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | ||

| Heating hot water | Inlet and outlet temperature ℃ | 55/70 | ||||||||

| Design flow m³/h | 6.7 | 13.3 | 20 | 26.7 | 33.3 | 40 | 53.3 | 66.7 | ||

| Pressure loss MPa | 0.02 | 0.02 | 0.03 | 0.03 | 0.03 | 0.04 | 0.04 | 0.04 | ||

| Take over caliber mm | DN40 | DN50 | DN80 | DN80 | DN80 | DN80 | DN100 | DN100 | ||

| Sanitary hot water | Inlet and outlet temperature ℃ | 20/60 | ||||||||

| Design flow m³/h | 2.2 | 4.4 | 6.7 | 8.9 | 11.1 | 13.3 | 17.8 | 22.2 | ||

| Pressure loss MPa | 0.01 | |||||||||

| Take over caliber mm | DN40 | DN50 | DN80 | DN80 | DN80 | DN80 | DN100 | DN100 | ||

| use pressure Mpa | 1 | |||||||||

| fuel | 0#Diesel oil | Consumption kg/h | 11 | 21 | 31 | 41 | 51 | 61 | 82 | 102 |

| Interface pipe diameter mm | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 | ||

| gas | Consumption Nm³/h | 28 | 55 | 82 | 110 | 137 | 164 | 219 | 274 | |

| Interface pipe diameter mm | 25 | 25 | 40 | 40 | 50 | 50 | 65 | 65 | ||

| natural gas | Consumption Nm³/h | 12 | 25 | 39 | 51 | 64 | 76 | 102 | 127 | |

| Orifice diameter mm | 25 | 25 | 40 | 40 | 50 | 50 | 65 | 65 | ||

| Exhaust caliber | 250*200 | 250*200 | 260*200 | 260*200 | 300*250 | 300*250 | 400*300 | 400*300 | ||

| Electrical power | Fuel oil kW | 0.76 | 0.76 | 0.76 | 0.76 | 1.4 | 1.4 | 2.6 | 2.6 | |

| Gas kW | 1 | 1 | 1 | 1 | 1.75 | 1.75 | 2.85 | 2.85 | ||

| Dimensions | length mm | 2100 | 2460 | 2215 | 2215 | 3073 | 3073 | 3377 | 4120 | |

| width mm | 650 | 722 | 762 | 762 | 890 | 890 | 950 | 1110 | ||

| height mm | 1245 | 1620 | 1750 | 1750 | 1695 | 1695 | 1951 | 2253 | ||

| Shipping weight kg | 1300 | 1400 | 1450 | 1700 | 1900 | 2100 | 2400 | 2500 | ||

| model | VB-120 | VB-150 | VB-180 | VB-200 | VB-240 | VB-300 | VB-350 | ||

| Continuous output | 120 | 150 | 180 | 200 | 240 | 300 | 350 | ||

| Heating hot water | Inlet and outlet temperature ℃ | 55/70 | |||||||

| Design flow m³/h | 80 | 100 | 120 | 133.3 | 160 | 200 | 233.3 | ||

| Pressure loss MPa | 0.05 | 0.04 | 0.06 | 0.05 | 0.07 | 0.06 | 0.08 | ||

| Take over caliber mm | DN100 | DN125 | DN125 | DN150 | DN150 | DN200 | DN200 | ||

| Sanitary hot water | Inlet and outlet temperature ℃ | 20/60 | |||||||

| Design flow m³/h | 26.7 | 33.3 | 40 | 44.4 | 53.3 | 66.7 | 77.8 | ||

| Pressure loss MPa | 0.01 | ||||||||

| Take over caliber mm | DN100 | DN125 | DN125 | DN150 | DN150 | DN200 | DN200 | ||

| Shǐyòng yālì 4/5000 use pressure Mpa | 1 | ||||||||

| fuel | 0#Diesel oil | Consumption kg/h | 122 | 153 | 184 | 204 | 245 | 306 | 357 |

| Interface pipe diameter mm | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1 | ||

| gas | Consumption Nm³/h | 329 | 411 | 493 | 548 | 658 | 822 | 959 | |

| Interface pipe diameter mm | 80 | 80 | 80 | 100 | 100 | 125 | 125 | ||

| natural gas | Consumption Nm³/h | 153 | 191 | 228 | 254 | 306 | 383 | 446 | |

| Interface pipe diameter mm | 80 | 80 | 80 | 100 | 100 | 100 | 100 | ||

| Exhaust caliber | 400*300 | 500*300 | 500*300 | 600*400 | 600*400 | 700*400 | 700*400 | ||

| Electrical power | Fuel oil kW | 2.6 | 4 | 4.5 | 4.5 | 6.5 | 9 | 9 | |

| Gas kW | 2.85 | 4.5 | 5 | 5 | 7 | 9.5 | 9.5 | ||

| Dimensions | length mm | 4120 | 4535 | 4538 | 4880 | 4880 | 5300 | 5300 | |

| width mm | 1120 | 1440 | 1440 | 1480 | 1480 | 1500 | 1500 | ||

| height mm | 2253 | 2659 | 2659 | 2942 | 2942 | 3400 | 3400 | ||

| Shipping weight kg | 2500 | 3100 | 3100 | 4500 | 4500 | 5300 | 5300 | ||

The whole structure of the natural gas vacuum phase change boiler is a negative pressure hot water unit. The unit is equipped with burner and a smoke pipe. The unit uses natural gas to burn in the furnace through a burner, and the heat generated by the combustion heats the heat medium water. The air inside has been vacuum out before commissioning, and the machine is in a vacuum status. The heat medium water is heated to about 30℃ and then evaporate in a vacuum state. The steam heat the hot water flowing in the heat transfer tube to provide it to the outside world hot water or sanitary hot water or for heating.

Features:

(1)Energy saving, the utilization efficiency of natural gas is 94%, and the exhaust gas temperature is lower than 90℃;

(2)Non-pressure equipment, no need for professional design of boiler room, no need for professional installation team, no need for boiler certificate, low installation and operation cost;

(3)It can directly supply heat, save a set of plate heat exchanger and hot water pump, reduce equipment investment, and reduce the operation and maintenance cost of hot water pump;

(4)It can supply domestic hot water while heating;

(5)Omron PLC control, one-button start and stop operation, automatic operation at constant temperature, can also be started and stopped at a fixed time, saving manpower and material resources;

(6) Leak detection in five consecutive processes to ensure that the unit does not malfunction due to leakage;

(7)It has multiple protections such as over-temperature, over-pressure and cut-off, more reliable.

"Safety, Attention, and Stability"