1、The unit uses waste heat and waste heat for refrigeration,almost no energy is needed.Operation cost is very low;

2、Each chamber inside the unit is designed with vacuum insulation layer to reduce internal heat loss and improve unit efficiency;

3、The COP of low temperature hot water absorption lithium bromide refrigeration unit and 0.1MPa steam type absorption lithium bromide refrigeration unit is above 0.72;

4、The COP of vapor type (0.6 MPa, 0.8 MPa) absorption lithium bromide chiller is above 1.35;

Shandong Lucy New Energy Technology Co., Ltd. has been focusing on product innovation and performance improvement, constantly optimizing the structure and performance of absorption refrigeration units, and has made great progress in waste heat recovery and solar air conditioning. The company now has absorption air-conditioning units (5kW cooling capacity), and solar air-conditioning systems (11 years) with longest operation time in China, It is exported to Europe, Southeast Asia, America, Australia, West Asia and other regions and countries.

|

type |

energy |

application |

|

|

Standard product |

hot water absorption chiller |

hot water ,conduct oil(72-90 ºC) |

solar energy generator industry waste heat. |

|

assemble solar hot water absorption chiller |

solar hot water (72-90 ºC)(72-90 ºC) | school ,hall ,office, villa . | |

| steam operate double effect absorption chiller | steam (6bar ,8bar) | plant station, industry waste steam | |

| exhaust gas fired absorption chiller | high temperature exhaust gas (≥175 ºC) | generator , boiler exhaust gas | |

| natural gas fired absorption chiller | natural gas, gas ,biogas, diesel | hospital, hall, hotel, office. | |

| Non-standard models | two stage absorption chiller | low temperature hot water(≥65ºC) | industry hot water or solar hot water |

| twin times absorption chiller | big temperature in/out waste heat (90-70 ºC) | waste industry heat | |

| automatically change single /double effect absorption chiller | automatically change single /double effect absorption chiller | industry waste heat | |

| steam operate single effect absorption chiller | steam (1bar, 4bar) | plant, paper mill, industry steam | |

| exhaust &hot water absorption chiller | generator jacket water and exhaust gas | CCHP system | |

| small type absorption air cooling and air cold chiller | hot water (72-90 ºC) | villa family | |

steam operate double effect absorption chiller

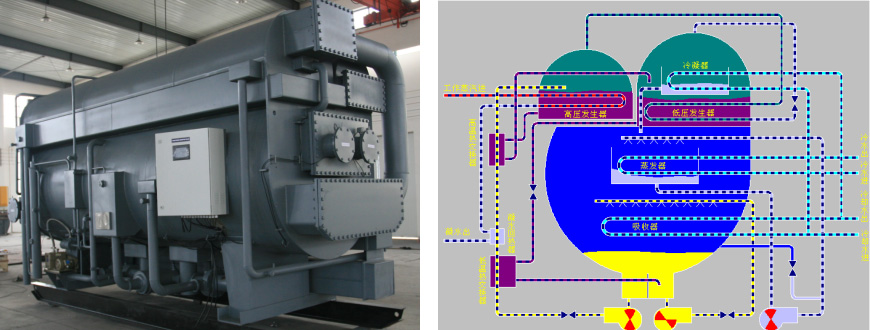

This kind of chiller mainly composed of 8 parts: high-temp generator, low-temp generator, condenser, evaporator, absorber, high-temperature heat exchanger, low-temperature heat exchanger and condensate heat exchanger.

0.6MPa steam operate double effect absorption chiller

|

Model number |

SXZ6- 350 | SXZ6- 465 | SXZ6- 580 | SXZ6- 700 | SXZ6- 930 | SXZ6- 1150 | SXZ6- 1450 | SXZ6- 1750 | SXZ6- 2300 | |

|

Rated cooling capacity kW |

350 | 465 | 580 | 700 | 930 | 1150 | 1450 | 1750 | 2300 | |

|

Working steam |

Steam consumption kg/h | 390 | 520 | 650 | 780 | 1040 | 1300 | 1560 | 1950 | 2600 |

| steam pressure | 0.6MPa | |||||||||

| Import pipe diameter | DN50 | DN50 | DN65 | DN65 | DN65 | DN80 | DN100 | DN100 | DN100 | |

| Outlet pipe diameter | DN25 | DN25 | DN25 | DN25 | DN32 | DN50 | DN50 | DN50 | DN50 | |

|

cold water |

Cold water flow m³/h | 60 | 80 | 100 | 120 | 160 | 200 | 240 | 300 | 400 |

| Inlet and outlet temperature | 12 / 7℃ | |||||||||

| Import and export pipe diameter | DN100 | DN100 | DN125 | DN125 | DN150 | DN150 | DN150 | DN200 | DN250 | |

| Pressure drop MPa | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | |

|

Cooling water

|

Cooling water flowm³/h | 90 | 120 | 150 | 180 | 240 | 300 | 360 | 450 | 600 |

| Inlet temperature | 30/35℃ | |||||||||

| Import and export pipe diameter | DN125 | DN125 | DN150 | DN150 | DN200 | DN200 | DN250 | DN250 | DN300 | |

| Pressure drop MPa | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.09 | |

|

Dimensions |

long mm | 3150 | 2960 | 3760 | 4590 | 5500 | 4810 | 4620 | 5637 | 7165 |

| width mm | 1700 | 1900 | 1900 | 1900 | 1900 | 2100 | 2150 | 2150 | 2150 | |

| high mm | 2350 | 2430 | 2430 | 2430 | 2430 | 2775 | 2985 | 2985 | 2985 | |

|

power consumption kW |

1.1 | 1.1 | 1.5 | 1.7 | 3.2 | 6.3 | 7.4 | 7.4 | 8.9 | |

|

Shipping weight kg |

5100 | 6400 | 7600 | 9100 | 10300 | 12100 | 14000 | 16500 | 19000 | |

Note:

1.The fouling of chilled water is 0.086m2 ℃ / kW.

2.Outlet temperature of steam condensate: less than 85 ℃

0.8MPa steam operate double effect absorption chiller

|

Model number |

SXZ8- 350 |

SXZ8- 465 |

SXZ8- 580 |

SXZ8- 700 |

SXZ8- 930 |

SXZ8- 1150 |

SXZ8- 1450 |

SXZ8- 1750 |

SXZ8- 2300 | |

|

Rated cooling capacity kW |

350 | 465 | 580 | 700 | 930 | 1150 | 1450 | 1750 | 2300 | |

| Working steam |

Steam consumption kg/h |

375 | 500 | 625 | 750 | 1000 | 1250 | 1500 | 1875 | 2500 |

|

steam pressure |

0.8MPa | |||||||||

|

Import pipe diameter |

DN50 | DN50 | DN65 | DN65 | DN65 | DN80 | DN100 | DN100 | DN100 | |

|

Outlet pipe diameter |

DN25 | DN25 | DN25 | DN25 | DN32 | DN50 | DN50 | DN50 | DN50 | |

| cold water |

Cold water flow m³/h |

60 | 80 | 100 | 120 | 160 | 200 | 240 | 300 | 400 |

|

Inlet and outlet temperature |

12 / 7℃ | |||||||||

|

Import and export pipe diameter |

DN100 | DN100 | DN125 | DN125 | DN150 | DN150 | DN150 | DN200 | DN250 | |

|

Pressure drop MPa |

0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | |

| Cooling water |

Cooling water flow m³/h |

90 | 120 | 150 | 180 | 240 | 300 | 360 | 450 | 600 |

|

Inlet and outlet temperature |

30/35℃ | |||||||||

|

Import and export pipe diameter |

DN125 | DN125 | DN150 | DN150 | DN200 | DN200 | DN250 | DN250 | DN300 | |

|

Pressure drop MPa |

0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.09 | |

| Dimensions |

length mm |

3150 | 2960 | 3760 | 4590 | 5200 | 4510 | 4120 | 5137 | 6365 |

|

width mm |

1700 | 1900 | 1900 | 1900 | 1900 | 2100 | 2150 | 2150 | 2150 | |

|

height mm |

2350 | 2430 | 2430 | 2430 | 2430 | 2775 | 2985 | 2985 | 2985 | |

|

power consumption kW |

1.1 | 1.1 | 1.5 | 1.7 | 3.2 | 6.3 | 7.4 | 7.4 | 8.9 | |

|

Shipping weight kg |

5000 | 6200 | 7400 | 8900 | 9700 | 12800 | 13500 | 15800 | 18000 | |

Note:

1.The fouling of chilled water is 0.086m2 ℃ / kW.

2.Outlet temperature of steam condensate: less than 85 ℃

When the unit is working, the light solution in the absorber is transported to the high temperature heat exchanger and the low temperature heat exchanger by the generating pump in two ways, and then enters the high temperature generator and the low temperature generator respectively after heat exchange and temperature rise.

When the dilute solution entering the high-temperature generator was heated to the evaporate point by the working steam, the high-temperature refrigerant steam is generated, which is go into the low-pressure generator to heat the dilute solution in the low-temperature generator, and then enters the condenser through throttling, finally cooled into refrigerant water. The refrigerant water produced by the high and low pressure generators is combined by the condenser water collector and then led into the evaporator.

The refrigerant water absorbs the heat of the refrigerant water in the evaporator and intensifies into water vapor. In the high and low pressure generators, the heavy solution enters the absorber and mixes with the water vapor from the evaporator. The water vapor is absorbed and recovered to the original concentration and becomes dilute solution. The dilute solution enters into the high and low pressure generator through the generator pump and continues to circulate.

1、The unit uses waste heat and waste heat for refrigeration,almost no energy is needed.Operation cost is very low;

2、Each chamber inside the unit is designed with vacuum insulation layer to reduce internal heat loss and improve unit efficiency;

3、The COP of low temperature hot water absorption lithium bromide refrigeration unit and 0.1MPa steam type absorption lithium bromide refrigeration unit is above 0.72;

4、The COP of vapor type (0.6 MPa, 0.8 MPa) absorption lithium bromide chiller is above 1.35;

5、The COP of direct fired absorption lithium bromide chiller is above 1.35;

6、Leak detection for five consecutive processes to ensure that the unit has no fault due to leakage;

7、High intelligent automatic control. The unit can be started up and shut down by "one key", with the function of fault alarm dilution and shutdown.

8、The control system directly or indirectly controls the cooling water pump, cooling water pump and cooling tower fan, which improves the overall efficiency of solar air conditioning system by 25%;

9、The color LCD touch screen is used in the computer automatic control, which can dynamically display the operating conditions of the unit. The screen has the function of fault recording and real-time recording of parameter operation curve.

10、The first-line brand control components are adopted: Omron CP1 series PLC, OmronLY2N-Jseries relay, Schneider IC65series circuit breaker, Schneider LC1-Dseries contactor, WEINVIEWtouch screen, WILO water pump of Germany. These components ensure the reliability of the control system hardware.

11、Fine workmanship ensures the service life of the unit is 23 years and 30 years.